Wear layer, 12mil, 20mil, 22mil--there’s enough vinyl flooring terminology out there to make your head spin. Don’t worry! We’re breaking these topics down and more, so you can approach your next build with these in-depth resources in mind.

What is LVT Flooring?

Solstone, Pelican's exclusive flooring division, leads the way in quality LVT (luxury vinyl tile) flooring. We offer an extensive range of vinyl flooring styles, suitable for various scenarios and price points. Today, we're going to analyze the anatomy of our flooring while explaining the benefits of each unique section--with a special focus on the wear layer.

Luxury vinyl tile is a type of flooring that closely mimics the appearance of natural wood or stone. Overtime, technology has advanced to include durability features and aesthetic choices that make LVT a worthy consideration for projects of all sorts. LVT is often referred to as LVP (luxury vinyl plank) as the terms are usually interchangeable. Our LVT flooring is comprised of stone polymer composite. It's a unique blend of stone powder and resin that results in a robust flooring choice.

But what makes Solstone flooring different? While each collection brings their own unique advantages (like the Metropolitan's large planks and seamless bevels, or the Woodland's realistic appeal), our flooring utilizes a special rigid core. We'll go over this section in more detail in just a moment.

LVT flooring is a great choice for uneven subfloors due to its durability. With proper installation and enough time to acclimate (expand) to its new environment (ex. being shipped from a warehouse to the project's air-conditioned space), LVT flooring will endure for years to come.

The Layers of LVT Flooring

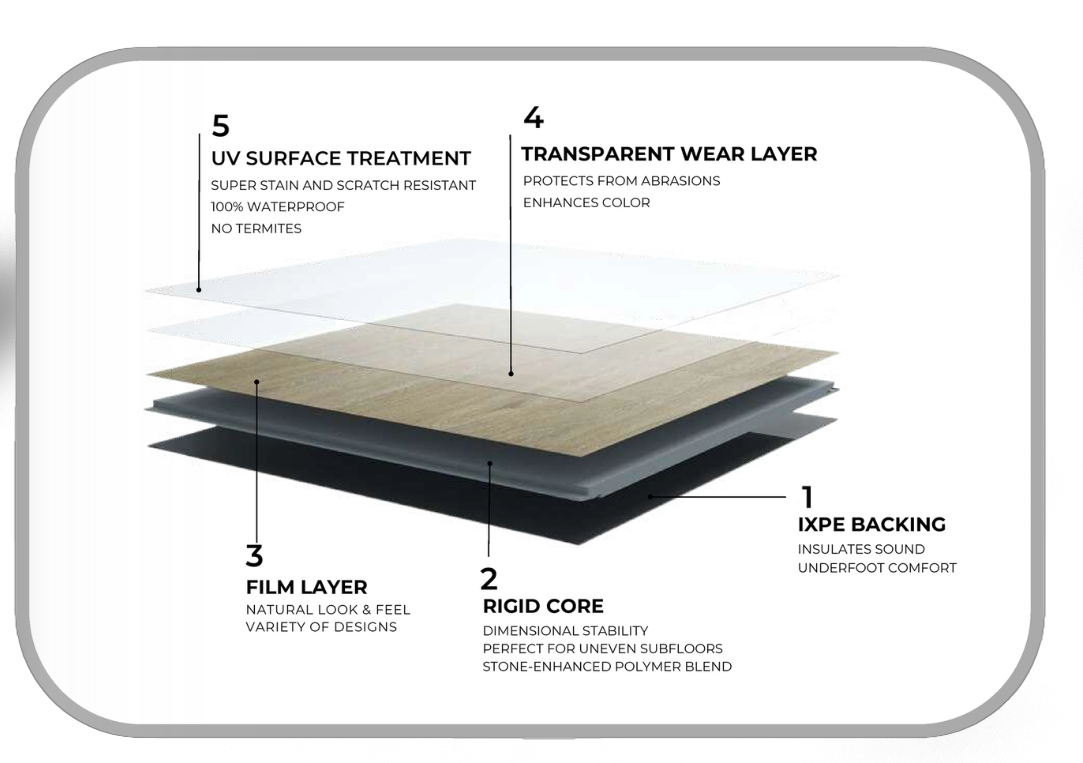

1) IXPE Backing: Let's start from the bottom. The IXPE pad is what the subfloor will come in contact with. Our flooring comes with this pad pre-attached, so you don't have to worry about adding it on yourself. This layer helps promote sound insultation and provides additional comfort to the user underfoot. We choose to go with a 1.0mm high density IXPE backing instead of the 1.5mm you might find with other flooring companies.

Good to Know: A thicker IXPE backing, like a 1.5mm backing, tends to add stress to the flooring, instead of adding durability. It specifically interferes with the flooring's locking system, meaning it may be difficult for the individual planks to remain securely attached. This leads to buckling and shifting floors, which are both aesthetically unpleasing and a hazard.

2) Rigid Core Layer: The rigid core is perhaps one of the most important pieces of our flooring. (Ask your account manager for a sample to test it out! Simply knock against this layer and you'll see how dense it really is). This density makes the flooring robust and resilient, adding strength and stability underfoot while remaining quiet (reducing any creaking noises you might come across in other flooring types, like wood).

Good to Know: Our flooring cores are made up of stone powder and virgin PVC for durability purposes. The core is phthalate and formaldehyde-free.

3) Film Layer: This decor layer is where an HD-printed graphic resides. This is where you'll notice our rich, vivid styles and the feel of natural stone or wood.

4) Transparent Wear Layer: While we'll break down this section in more detail, the wear layer is a unique transparent layer that protects the film layer from abrasions, scratches, and scuffs, and adds extra richness to the plank's tones.

5) UV Surface Treatment: This layer deflects water and adds additional resistance to scratches and stains. While it's advised to not leave SPC flooring in direct sunlight for extended periods of time, this layer helps prevent sun damage from light that may spill in from windows. This UV-cured polyurethane coating layer is an essential feature of SPC flooring that helps extend its lifespan and keeps it looking good with minimal maintenance.

How Is LVT Flooring Installed?

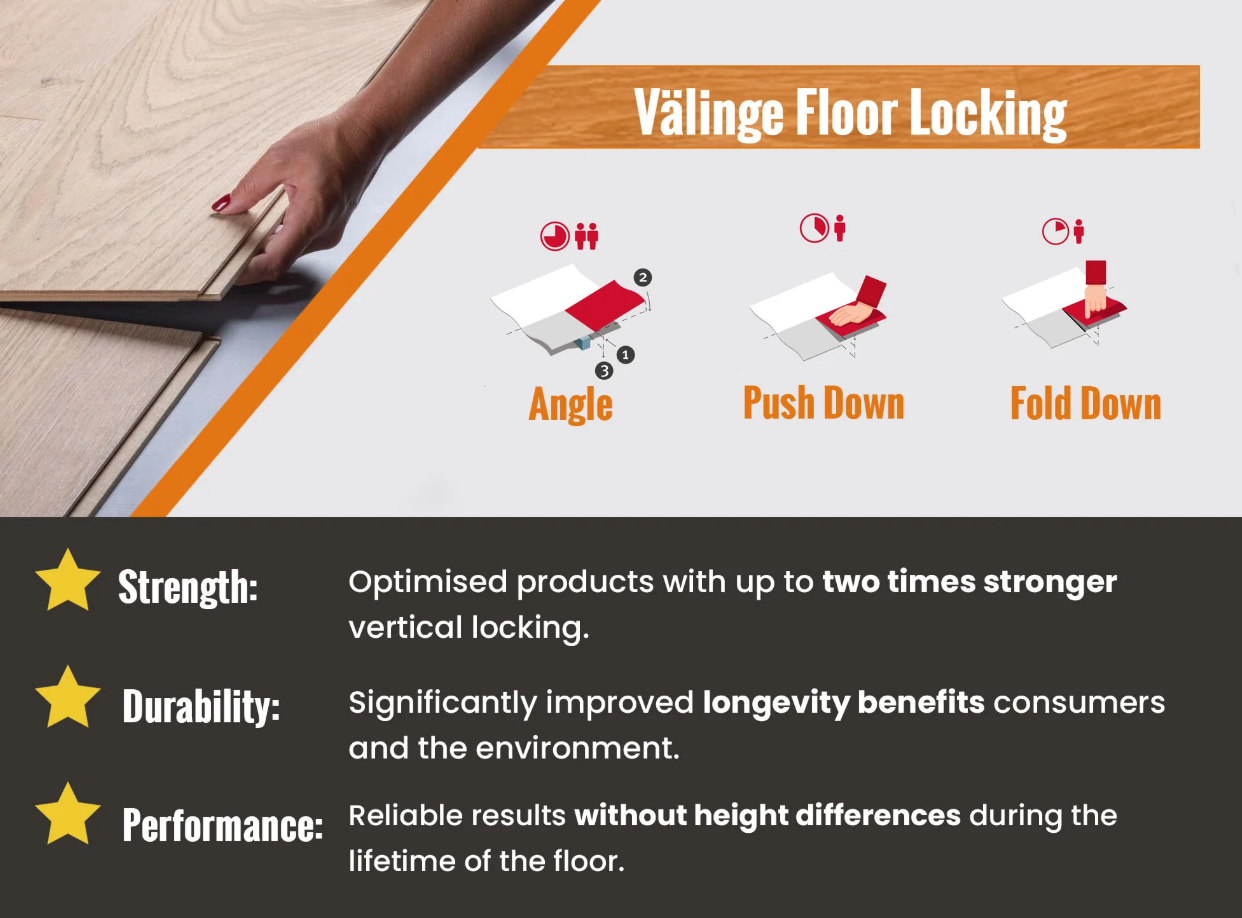

Another reason why LVT flooring is so popular is due to its ease of installation. Common installation types are loose-lay, click, or glue down. Our vinyl flooring uses a specialized locking system (Uniclic or Valinge). Our Metropolitan XL Collection and Coastal Collection utilize Uniclic installation. Our Woodland Collection utilizes a Valinge locking system. While these two systems are very similar, installation varies slightly--view the fact sheets below to see how.

Our click lock system is easy to use: just line up the edges and snap them into place. Because of the tightness of these joints, this prevents water from seeping into the surface below.

So, What is a Wear Layer?

When choosing your vinyl flooring, selecting the right wear layer is essential. The wear layer refers to a special section at the top of the plank. The wear layer is transparent, letting details show through, such as texture.

A wear layer isn’t just an aesthetic choice. It helps preserve the integrity of the flooring, adding extra durability. Great wear layers not only deflect stains and moisture absorption, but also provide another line of defense against scratches and heavy wear and tear.

While most vinyl flooring boast a wear layer, it’s important to pay careful attention to the wear layer's actual thickness—as this impacts the flooring’s overall longevity.

Common Wear Layer Thicknesses

You might have come across the terms “mm” and “mil” while doing your vinyl flooring research. While these are both terms of measurement, what they’re actually measuring is very different.

“Mm” stands for millimeters. This is the flooring’s overall thickness—counting for all possible layers. Depending on the quality of your vinyl flooring, this may include an IXPE foam underlay, a rigid core section, a decorative layer, the wear layer, and a UV layer.

The word “mil” specifically refers to the thickness of the wear layer. The most common wear layer thicknesses are 12mil, 20mil, and 22mil. 12mil is the least thick, whereas 22mil is the thickest. A 20mil wear layer is roughly 0.5 mm thick and a 22mil wear layer is 0.55mm thick. A rising trend is 30mil flooring, and while some flooring companies may offer this type of flooring, we have strong reasons to advise against it!

Why Shouldn't I Choose a 30mil Wear Layer?

Our latest flooring series, the Metropolitan Collection XL, comes with two of the most popular and hardiest wear layer options. The series is available in either 6.0mm overall thickness with a wear layer of 20mil, or a 7.0mm overall thickness with a wear layer of 22mil.

You might wonder why we didn't choose a 30mil wear layer instead. While 30mil wear layer thickness is becoming popular in the vinyl flooring industry, there are significant drawbacks. At first, it might seem like a 30mil thickness provides ample protection and peace of mind. In reality, wear layers beyond 22mil aren't always superior.

A wear layer that's too thick might make your vinyl flooring lose its charm. Vinyl flooring is well known for its ability to capture intricate detail and realism that's found in wooden floorboards. This is referred to as "embossment." A thick wear layer, such as the 30mil, can cause the embossment to shift and flex, leading to small imperfections that become rather noticeable in years to come.

Another reason to stay away from 30mil? The cost. 30mil is typically more expensive than 22mil. 20mil and 22mil are very durable, and a cost-effective solution due to their longevity.

Choosing the Right Wear Layer for Your Project

While vinyl flooring is typically rugged, we understand that every project has its unique requirements. Budget certainly comes into play, as well as where the flooring is going to be located in the first place. A busy shopping center has different requirements than a two-bedroom apartment, and we wouldn't expect the same flooring type to apply to all spaces. Remember: the higher the number, the thicker the wear layer.

When to Use 20mil Flooring:

While 20mil is certainly a reliable option, it really shines in areas with light commercial traffic, like an office space, or apartments.

When to Use 22mil Flooring:

22mil flooring is perfect for areas that will receive high-impact traffic. Think retail stores and university spaces. While our vinyl flooring certainly withstands water absorption and staining, 22mil is an even better option for kitchens and bathrooms that face frequent moisture.

Is 12mil Enough?

12mil flooring shouldn't be overlooked! While 20mil and 22mil are very durable, 12mil is perfectly fine for residential spaces. While 20mil and 22mil last longer overall, 12mil is robust enough even for busy families to frequently use. For budget-conscious planning, this option is a great choice.

-v1740757234170.jpg)

Enhancing the Wear Layer: DiamondDust and UltraShield

We mentioned earlier that our Metropolitan Collection features both 20mil and 22mil options. We've also added Solstone-exclusive wear layer types: DiamondDust and UltraShield. These are enhanced wear layers that provide even more protection against hectic scenarios. Want a deeper dive? View our blog post about this latest edition.

Sound Ratings Matter

When building multi-family residences, it's important to keep into account the flooring's sound ratings. We've tested our flooring for two important details - Impact Insulation Class (IIC) and Sound Transmission (STC).

The market standard for IIC is 55+ (with an underlayment). Our IIC rating for our SPC vinyl flooring is 62.

The market standard for STC an STC rating is 50+. Our SPC vinyl flooring has an STC score of 63.

Give your clients flooring that won't disturb their peace of mind!

Now that you have a deeper understanding about wear layers and their functions, we hope we've made it easier for you to decide which flooring might be the ideal solution for you. Still need assistance? We're happy to help. Contact us today or swing by our Clearwater showroom for guidance.